Whether you’re a first-time traveler or a frequent flyer, picking the suitable travel cases for all your valuables

and personal belongings can make a world of difference. For example, can your carry-on or store your things securely in it? Is your Dopp kit completely leak-proof? And more importantly, can your case withstand the heat, moisture, tension, and rigidity that may occur during the transport?

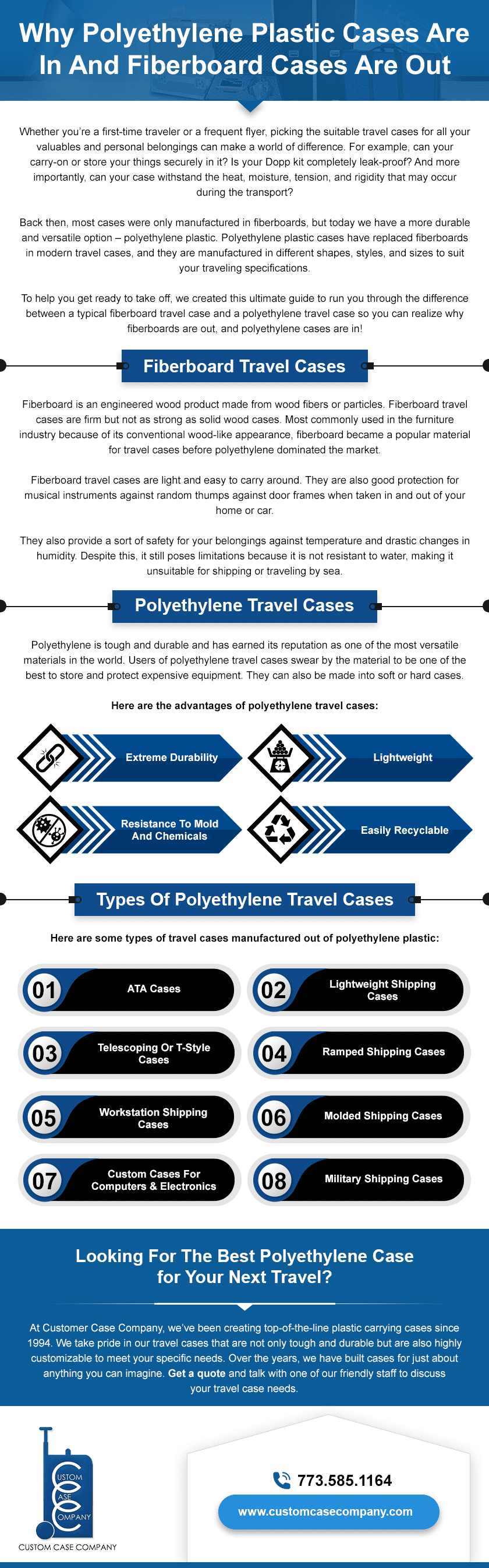

Back then, most cases were only manufactured in fiberboards, but today we have a more durable and versatile option – polyethylene plastic. Polyethylene plastic cases have replaced fiberboards in modern travel cases, and they are manufactured in different shapes, styles, and sizes to suit your traveling specifications.

To help you get ready to take off, we created this ultimate guide to run you through the difference between a typical fiberboard travel case and a polyethylene travel case so you can realize why fiberboards are out, and polyethylene cases are in!

Fiberboard Travel Cases

Fiberboard is an engineered wood product made from wood fibers or particles. Fiberboard travel cases are firm but not as strong as solid wood cases. Most commonly used in the furniture industry because of its conventional wood-like appearance, fiberboard became a popular material for travel cases before polyethylene dominated the market.

Fiberboard travel cases are light and easy to carry around. They are also good protection for musical instruments against random thumps against door frames when taken in and out of your home or car.

They also provide a sort of safety for your belongings against temperature and drastic changes in humidity. Despite this, it still poses limitations because it is not resistant to water, making it unsuitable for shipping or traveling by sea.

Polyethylene Travel Cases

Polyethylene is tough and durable and has earned its reputation as one of the most versatile materials in the world. Users of polyethylene travel cases swear by the material to be one of the best to store and protect expensive equipment. They can also be made into soft or hard cases.

Here are the advantages of polyethylene travel cases:

Extreme Durability

Polyethylene is considered one of the most durable forms of plastic. You can easily count on it to endure the rigors of shipping, traveling, and transport, as well as sudden drops and spikes in temperature that may arise during the trip.

Lightweight

While they leave no doubts about durability, it is also a favorite among travelers because its lightweight properties make it much easier for users to move from place to place. A light case can also save you so much shipping or check-in costs.

Resistance To Mold And Chemicals

Did you accidentally spill coffee on your polyethylene travel case? Were you able to move your case from your car to your house during a downpour? Did you not worry that it would accumulate molds or mildew when stored? If you have said yes to any of these and own a polyethylene travel case, it is proof that your case is in excellent condition and resistant to chemicals, moisture, mildew, and mold.

Easily Recyclable

Although polyethylene plastic travel cases are meant to last you a lifetime, it is also one of the most sustainable plastics on the planet. All polyethylene plastics are categorized with a resin identification code for recycling purposes. Today, almost all curbside recycling programs accept polyethylene plastic.

Types Of Polyethylene Travel Cases

Here are some types of travel cases manufactured out of polyethylene plastic:

ATA Cases

These cases are designed based on an airplane parts packaging specification developed by airline packaging engineers. They are designed to withstand the rigors of being shipped a minimum of 100 times. This standard also specifies that the case has handles that will not break during transit and should be made of non-corrosive materials.

Lightweight Shipping Cases

Though they don’t offer quite as much durability as ATA cases, these cases make handling easier while reducing shipping costs.

Telescoping Or T-Style Cases

These carrying cases have their lid slides over the base and is held together with straps. These cases do not use hinges or latches but can have wheels.

Ramped Shipping Cases

Typically on wheels for easy moving, ramped shipping cases feature a custom ramp that drops down to simplify equipment loading and unloading.

Workstation Shipping Cases

The cases form a complete workstation on the go and may include options such as drawers, bins, flat working surfaces, fold-out tables, and more.

Molded Shipping Cases

These cases withstand rough treatment, vibration, and extreme temperatures while still being easy to handle.

Custom Cases For Computers & Electronics

Delicate and expensive equipment requires careful handling to prevent damage. This type of optimal electronic equipment case helps prolong the lifespan of the equipment, protecting it during shipping, travel, and daily life.

Military Shipping Cases

From the name and application use – military. These cases can withstand extreme conditions. They typically have comfort grip handles, reinforced corners and edges for additional impact protection, a built-in anti-shear combination lock, a full-length piano hinge, and twist-draw latches. They also have molded-in ribs and corrugations for added columnar strength and protection.

Looking For The Best Polyethylene Case for Your Next Travel?

At Customer Case Company, we’ve been creating top-of-the-line plastic carrying cases since 1994. We take pride in our travel cases that are not only tough and durable but are also highly customizable to meet your specific needs. Over the years, we have built cases for just about anything you can imagine. Get a quote and talk with one of our friendly staff to discuss your travel case needs.