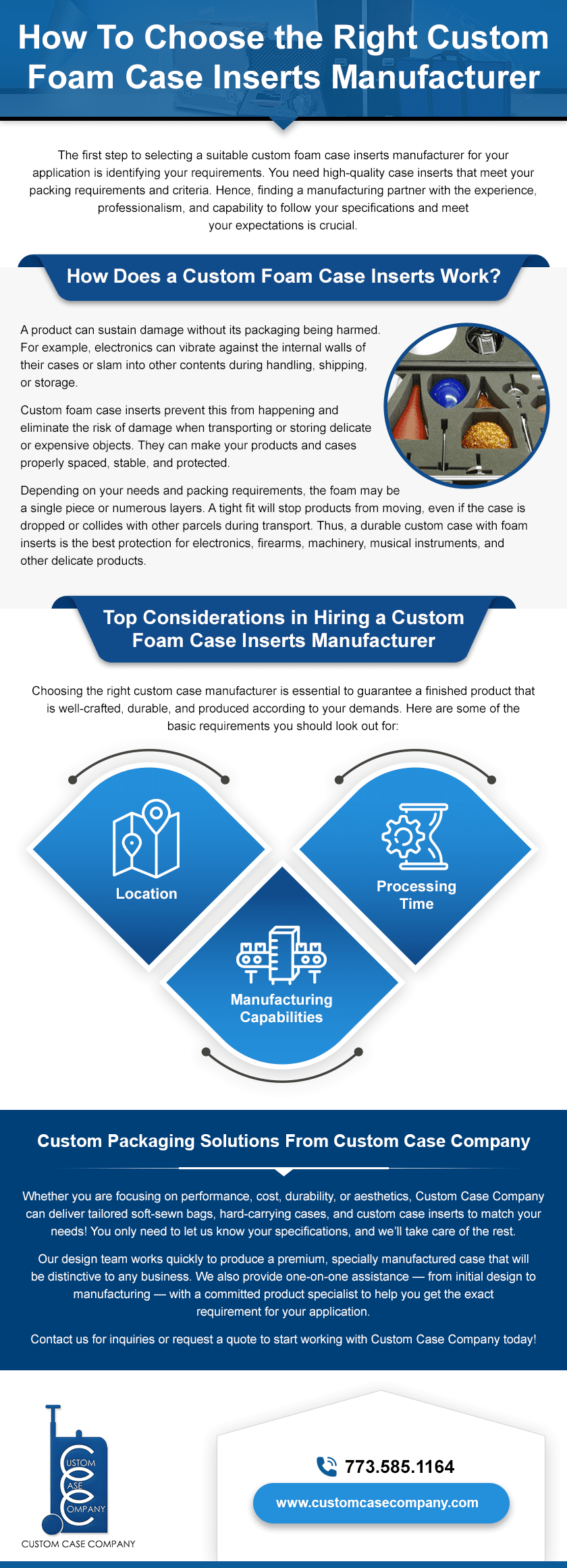

The first step to selecting a suitable custom foam case inserts manufacturer for your application is identifying your requirements. You need high-quality case inserts that meet your packing requirements and criteria. Hence, finding a manufacturing partner with the experience, professionalism, and capability to follow your specifications and meet your expectations is crucial.

How Does a Custom Foam Case Inserts Work?

A product can sustain damage without its packaging being harmed. For example, electronics can vibrate against the internal walls of their cases or slam into other contents during handling, shipping, or storage.

Custom foam case inserts prevent this from happening and eliminate the risk of damage when transporting or storing delicate or expensive objects. They can make your products and cases properly spaced, stable, and protected.

Depending on your needs and packing requirements, the foam may be a single piece or numerous layers. A tight fit will stop products from moving, even if the case is dropped or collides with other parcels during transport. Thus, a durable custom case with foam inserts is the best protection for electronics, firearms, machinery, musical instruments, and other delicate products.

Top Considerations in Hiring a Custom Foam Case Inserts Manufacturer

Choosing the right custom case manufacturer is essential to guarantee a finished product that is well-crafted, durable, and produced according to your demands. Here are some of the basic requirements you should look out for:

Location

While the pricing of foreign custom case manufacturers may be lower upfront, you are likely to encounter exorbitant shipping fees. Moreover, you have to wait longer for your custom foam cases to arrive, delaying production and delivery schedules.

Choosing a custom case maker based in the US can guarantee quick and inexpensive delivery. Doing so also lets you check the quality of orders and ensure they meet your expectations.

Processing Time

Turnaround estimates vary amongst foam case manufacturers. Inquire in advance about the anticipated length of the procedure. Can they finish the job on time for your application? Setting realistic expectations with your manufacturer is also important, as it will give you time to request modifications or improvements if necessary.

Manufacturing Capabilities

To ensure that you get the full value of your investment, choose a custom case foam inserts manufacturer capable of the following services:

- Consultation and packaging strategy

- Structural engineering and design

- Visual design

- Prototyping

- Hassle-free logistics

Check if they can work with foam, metal, plastics, and other materials you may require. Moreover, you must partner with a company capable of short-run and high-volume productions to help you streamline your production processes and operations.

Custom Packaging Solutions From Custom Case Company

Whether you are focusing on performance, cost, durability, or aesthetics, Custom Case Company can deliver tailored soft-sewn bags, hard-carrying cases, and custom case inserts to match your needs! You only need to let us know your specifications, and we’ll take care of the rest.

Our design team works quickly to produce a premium, specially manufactured case that will be distinctive to any business. We also provide one-on-one assistance — from initial design to manufacturing — with a committed product specialist to help you get the exact requirement for your application.

Contact us for inquiries or request a quote to start working with Custom Case Company today!